roughing end mill depth of cut

The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

End Mill An Overview Sciencedirect Topics

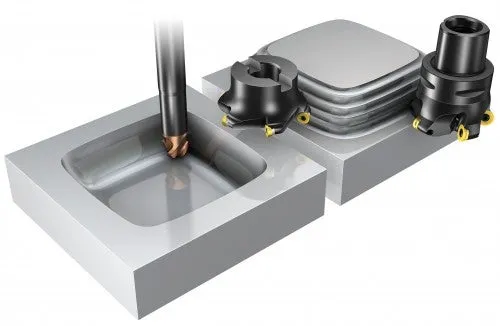

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

. Switching from mist to. Objective of finish pass is to improve surface finish dimensional accuracy and tolerance. Also for the same reason the depth of cut for semi-finishing end mills can be increased.

Now choose the right surface feet per minute SFM or surface meters per minute SMM. Cobalt roughing end mills are designed. A reduced entry angle spreads depth of cut over a greater cutting-edge length and thins the chip so at a 45-degree entrance angle chip thickness.

Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. 45 high helix flute design. Running program the other day and i notice broken 58 dia roughing HSS end mill.

Depth of cut Revolution min-1 Feed rate mmmin Revolution min-1 Feed rate mmmin Dia. Which improves end mill life and prevents depth-ofcut notching. It is possibler to gash a rougher on a tool cutter grinder or even a pedestal grinder with a hand-formed saucer.

The distance between scallops is referred to as pitch. Cutting speeds also vary with the end mill type - roughing end mills can go. 1st Maximum Cutting Depth.

End Mill Terms A - Mill Size or Cutting Diameter B - Shank Diameter C - Length of Cut or Flute Length. This results in lower cutting pressures at a given radial depth of cut. High-Performance Solid Carbide Roughing End Mills Solid Carbide End Mill for Roughing of Steels and Stainless Steel F4BJ-DL Radiused 3 Flutes Short Long Weldon Shank Metric List price.

Its typical for depth of cut to be set at 2. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Higher feed rate and depth of cut are utilized.

I replaced end mill and rerun and see end mill goes in a drilled hole 125 deep and feeds to 2nd hole a inch away at 20 ipm feed which i slow to 15 ipm feed so end mill does not break again. Very low feed rate and depth of cut are utilized. Cut Depth 05mm Pf04mm.

Due to variable spacing of flutes combined with the NR roughing profile vibrations cutting forces are minimized and metal removal rates are maximized. End Mill Speed Feed Calculator. Optimized roughing is based on end mill angle of engagement and its effects on end mill life chip thickness and workpiece quality.

Increasing your coolant pressure or if you use mist increasing the air pressure. The tooth design and flute construction minimizes deflection and maximizes chip ejection. Normally a 20 reduction in effective horsepower is used.

Cutting tool utilization and metal removal can be maximized by fully engaging the solid carbide end mill. CLF based on the radial depth of cut. Mm Aluminum alloy A7075 Cast aluminium AC4B.

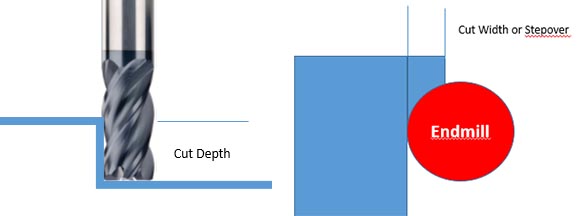

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. Increasing Depth of Cut or Stepover may require you to do a better job chip clearing. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use.

Aiming the coolant nozzle better to clear chips from the cut. Roughing end mill Short cut length 3 flute For aluminium alloy Corner radius roughing end mill Short cut length 3 flute For aluminium alloy. Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills.

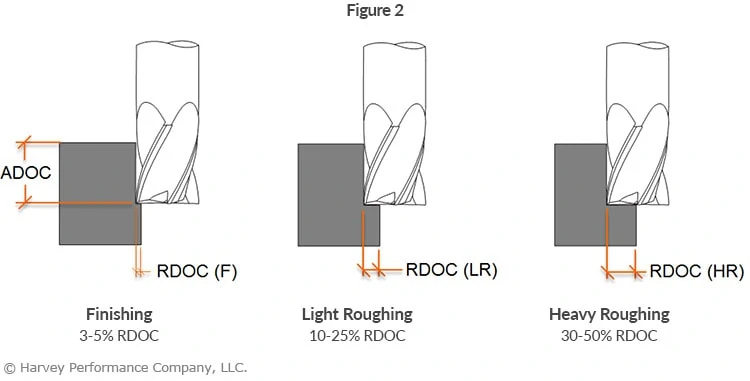

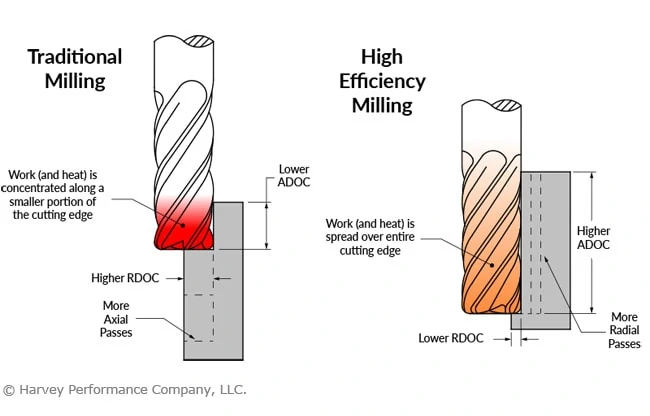

While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEMHEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. This means a 050-inch end mill will be engaged 0025 to 0050 inch.

The depth of cut plays a vital role in optimizing roughing. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. 13157771 Mfr Part.

End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. Login Dear Customers Our supplier HTC is having substantial problems with supply chains due to Covid-19. I am creating a new calculator based on your feedback.

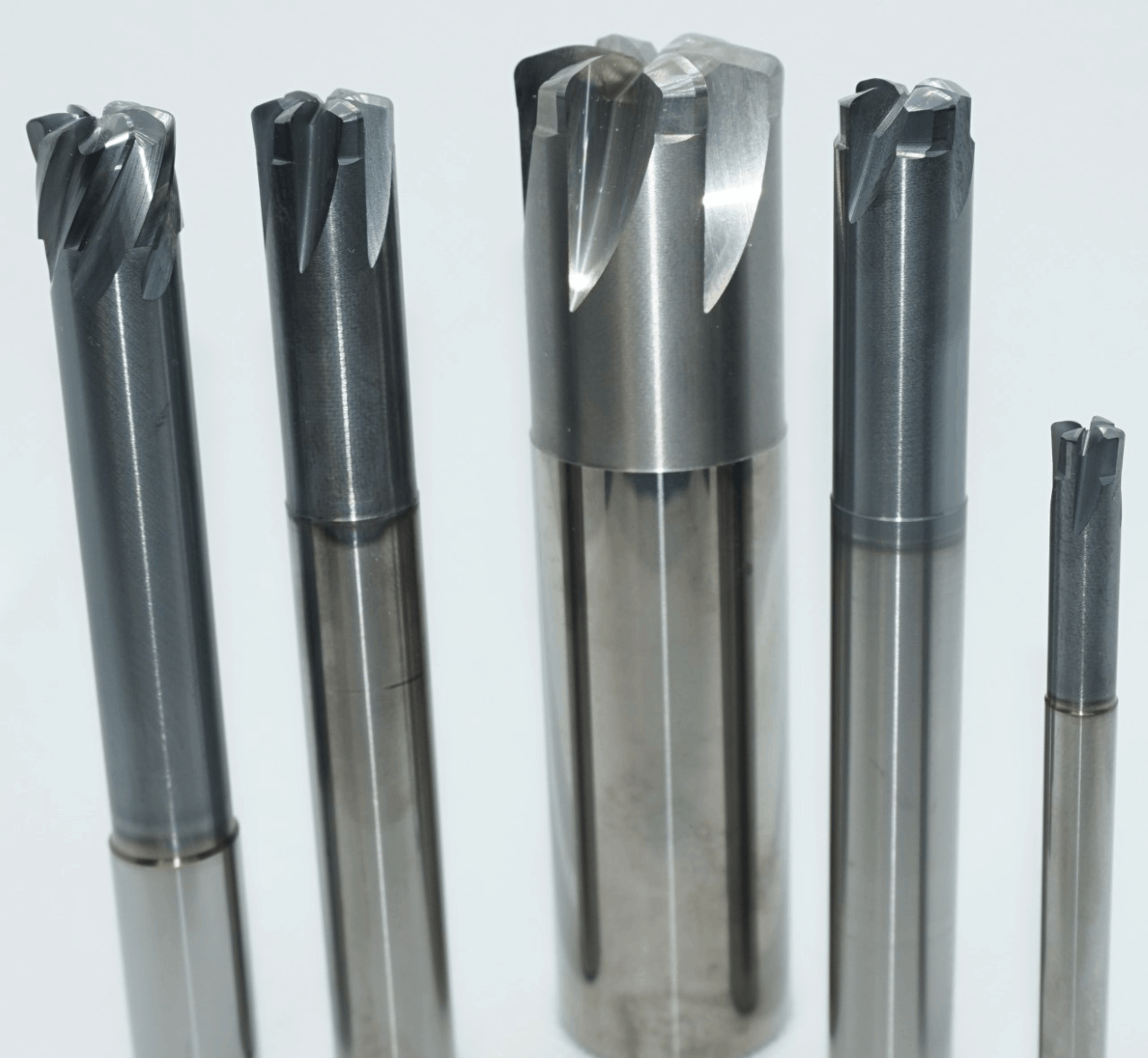

The deeper you go the slower you need to go. The image is showing. Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project.

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure. Carbide Square End Mills.

Multifunctional End Mill for High Speed Roughing and Precise Side Milling Work Materials. Climb cut is recommended for side milling. 720000 L Overall Length.

Objective of rough pass is to remove bulk amount of excess material from workpiece in every pass. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Vibration dampening variable flute spacing 45 high helix flute design Stabilizing cutting edge geometry PVD applied.

Volumes of material can be removed at high cutting speed. Multi-Cut end mills are specifically designed for high-performance roughing operations. This is because the cutting resistance is reduced because the chips are broken into short lengths by the wavy cutting edges.

Cobalt roughing end mills are designed to withstand heat and abrasion and can be run at higher production rates without sacrificing tool life. 220000 AP1MAX 1st Maximum Cutting Depth8661 L Overall Length. That can mean such things as.

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. Roughers have chip-breaker cutting edges the peaks. Speeds and feeds charts for end mills from The Carbide End Mill Store.

Max depth of cut slotting with roughing end mills. For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter. Guhring Optimized Roughing End Mill for Aluminum 600mm Diameter 60mm Shank 1300mm Length of Cut 65mm Overall - MSC Part.

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is sharpened by grinding the outside of the cutter.

Cnc Programming Archives Page 2 Of 2 Harvey Performance Company

Practical Machinist Largest Manufacturing Technology Forum On The Web

Endmill Selection Guide Redline Tools Redline Tools

Optimize Depth Of Cut And Stepover For Better Cnc Milling

End Mill An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

8 Ways You Re Killing Your End Mill In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co

Practical Machinist Largest Manufacturing Technology Forum On The Web

End Mill An Overview Sciencedirect Topics

The Secret Mechanics Of High Feed End Mills In The Loupe

Speed Feed Recs Melin Tool Company

4 6 Flute High Feed End Mills Epic Tool

Cutting Conditions For Rough Cutting Download Table

Difference Between Roughing And Finishing In Machining

Advanced Roughing Strategies Faster Through Optimized Toolpaths Secotools Com

Speed Feed Recs Melin Tool Company

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool